Mechanochemical Reversible Complexation Mediated Polymerization Enabled Synthesis of Fluorinated Polyacrylate Copolymers for Room Temperature Solid-State Lithium Batteries

Ziye Ren1,2, Pan Mei2, Chenyu Wang1,2, Du Chen1,2, Li Zhang1,2, Wei Zhang2(张伟)*, Zhao Wang1,2(王召)*, Zhengbiao Zhang1,2,3(张正彪)*

1State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, Suzhou 215123, China

2College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou 215123, China

3State Key Laboratory of Radiation Medicine and Protection, Soochow University,Suzhou 215123, China

Macromolecules2025, 58, 3199–3207

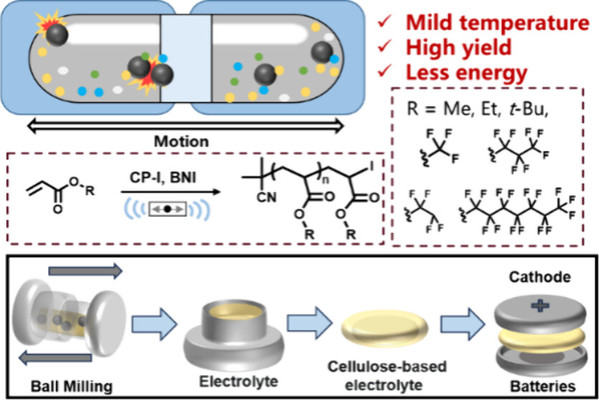

Abstract:Solid polymer electrolytes (SPEs) have garnered significant interest in the advancement of solid-state lithium batteries (SSBs) due to their excellent safety, processability, and lightweight features. Currently, there is an urgent demand for the green synthesis of high performance SPEs for applications in SSBs. In this study, we report a one-pot mechanochemical reversible complexation mediated polymerization (mechano-RCMP) approach to synthesize fluorinated polyacrylates under solventless conditions. The mechano-RCMP approach demonstrated an efficient controlled polymerization process with quantitative monomer conversion through force induced activation of the carbon–iodine bond. The chain extension experiments confirmed the high chain-end functional groups of the polymers. Further copolymerization of heptafluorobutyl acrylate (HFBA) with butyl acrylate (BA) and methoxy polyethylene glycol acrylate (mPEG) resulted in the formation of P(BA-co-HFBA-co-mPEG), which demonstrated high thermal stability and amorphous characteristics. This copolymer film exhibited a wide electrochemical window (upper cutoff voltage up to 5.4 V) and high Li+ conductivity (1.3 × 10–4 S cm–1 at 30 °C). SSBs fabricated with the P(BA-co-HFBA-co-mPEG) film showed good cycling performance, maintaining a capacity retention of 98% after 100 cycles at room temperature.

Article information: //doi.org/10.1021/acs.macromol.4c02983